DOUBLE JACKET ADSS CABLES

Product ‣ Outdoor Cables ‣ Double Jacket ADSS Cables

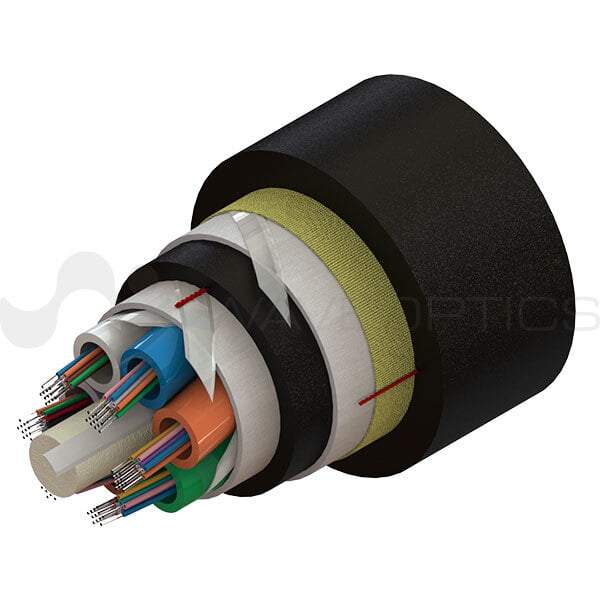

Double Jacket ADSS Cable

Waveoptics® Double Jacket ADSS Cable is designed for self-supporting and duct applications for cable spans up to 1,050 feet, allowing an easy and cost-effective one-step installation using standard hardware and installation methods. Reduced weight design and smaller diameter allows the usage of smaller ducts.

Loose tubes are made of PBT which provide great mechanical properties under a wide range of conditions such as crush test and impact test, and are filled with water blocking gel.

PE double jacket with additives makes a resistant, durable and easy to strip cable, providing superior protection against UV radiation, fungus, abrasion and other environmental factors.

The SZ-stranded method for loose tubes and four ripcords ensure a quick and easy mid-span access.

Dielectric central strength member requires no bonding or grounding.

Applications

Protections

Design Properties

| Fiber per Tube | 2 - 12 |

| Dielectric Strength Member | FRP |

| Outer Jacket Material / Thickness | Polyethylene / 1.55 mm (0.06 in) |

| Inner Jacket Material / Thickness | Polyethylene / 0.8 mm (0.03 in) |

| Loose Tube Diameter | 2.2 mm (0.09 in) |

| Drum Length | 10,000 ft, 15,000 ft, & 20,000 ft (±5%) |

Temperature Range

| Operation | -40°C to 70°C (-40°F to 158°F) |

| Installation | -30°C to 70°C (-22°F to 158°F) |

| Storage / Transport | -40°C to 70°C (-40°F to 158°F) |

Mechanical Properties

| Crush Resistance (Short-Term / Long-Term) | 3,000 N/100mm / 1,500 N/100mm |

| Minimum Bend Radius (Operation / Installation) | 10 x OD / 20 x OD |

Double Jacket ADSS

Track-Resistant Cable

Waveoptics® Double Jacket ADSS Track-Resistant Cable is designed for self-supporting applications for cable spans up to 1,050 feet, allowing an easy and cost-effective one-step installation using standard hardware and installation methods. Reduced weight design and smaller diameter allows a higher density of fiber using existing pole hardware.

Track-resistant PE (TRPE) double jacket with additives makes a resistant, durable and easy to strip cable, providing superior protection against UV radiation, fungus, abrasion and other environmental factors. Available for high voltage transmission lines for the following electric field potential ranges: 12 kV to 25 kV and higher than 25 kV up to 400 kV.

The SZ-stranded method for loose tubes and four ripcords ensure a quick and easy mid-span access.

Dielectric central strength member requires no bonding or grounding.

Applications

Protections

Design Properties

| Fiber per Tube | 2 - 12 |

| Dielectric Strength Member | FRP |

| Outer Jacket Material / Thickness | Track-Resistant Polyethylene / 1.55 mm (0.06 in) |

| Inner Jacket Material / Thickness | Polyethylene / 0.8 mm (0.03 in) |

| Loose Tube Diameter | 2.5 mm (0.08 in) |

| Drum Length | 10,000 ft. 15,000 ft & 20,000 ft (±5%) |

Temperature Range

| Operation | -40°C to 70°C (-40°F to 158°F) |

| Installation | -30°C to 70°C (-22°F to 158°F) |

| Storage / Transport | -40°C to 70°C (-40°F to 158°F) |

Mechanical Properties

| Crush Resistance (Short-Term / Long-Term) | 3,000 N/100mm / 1,500 N/100mm |

| Minimum Bend Radius (Operation / Installation) | 10 x OD / 20 x OD |